Free Industrial Building Maintenance Checklists ( Printables )

Recommandés

The complex machinery and infrastructure inherent to industrial facilities demands vigilant maintenance oversight. An Industrial Building Maintenance Checklist Form provides structure for proactive upkeep across a building’s vital systems. By standardizing inspections and tasks, it helps safeguard operational continuity, compliance, and cost control while extending equipment lifespan.

What Precisely Is Such a Form?

An Industrial Building Maintenance Checklist Form is a document dividing maintenance into sections for HVAC, electrical, safety gear, and more. It assigns parties and deadlines to specific checks, using checkboxes to mark completions and notes for follow-ups. This ensures critical components receive consistent, methodical attention.

Why Prove So Useful?

Preventive maintenance via regular inspections pinpoints issues beforehand, avoiding costly repairs or downtime.

- Safety compliance with health, fire, and other regulations requires documentation of inspection up-to-dates.

- Operational continuity relies on avoiding unexpected failures from one malfunctioning system like HVAC or electrical.

- Proactive upkeep cuts long-term ownership costs by lengthening equipment and infrastructure lifespans.

- Audit readiness necessitates a history’s presentation during regulated industry audits.

Checklist Composition and Structure

A well-designed checklist typically includes key details.

System and component inspections receive divisions with responsible parties, due dates, and a status tracker.

Notes foster follow-through on observations.

By standardizing and documenting maintenance through all functional areas, facilities optimize efficiency, safety, and financial stewardship.

Key Maintenance Areas

- General Building Inspection: Walls, flooring, roofing, and doors demand careful scrutiny.

- Electrical: Panels and emergency systems must also be examined.

- HVAC Systems: Ductwork and air conditioning deserve diligent review.

- Plumbing: Fixtures, drainage systems, and hot water heaters warrant inspection.

- Safety Gear: Fire extinguishers and the functioning of smoke detectors require verification along with proper signage and unblocked emergency exits.

- Exterior Grounds: Parking areas and walkways necessitate assessment, as does fencing and external signage.

Inspection dates and assigned responsibilities, plus task statuses and remarks, belong in documentation.

Digital Transformation of Checklists

Digitizing maintenance checklists eases updates and organizes data.

- Regular reviews, whether monthly, quarterly, or annually, rely on system importance.

- Assigning individuals and teams responsibility for each task proves crucial.

- A log tracking issues and repairs connects to tasks requiring follow-through.

- Tailoring checklists to unique building needs and equipment personalizes process.

More Than Administration: A Strategic Tool

Checklists do more than administration—they strategize longevity, safety, and efficiency.

Investing in consistent checklists:

- Reduces risk

- Ensures standards

- Optimizes operations

Regardless of size, well-constructed checklists prevent oversight.

It is a simple yet powerful habit, forming the foundation of a smoothly operating facility.

Why Routine Inspection is Paramount for Industrial Complexes

The intricate systems and infrastructure within industrial buildings require far more than occasional spot checks—they demand continuous, structured oversight. A thoughtfully constructed Industrial Facility Inspection Protocol brings the necessary rigor into daily operations, allowing facilities to function efficiently, securely, and in adherence with vital regulations.

By establishing regular routines for reviews and maintenance duties, this protocol ensures that each essential mechanism—whether environmental controls, electrical wiring, or emergency responses—receives focused attention at standard intervals. The outcome? Fewer breakdowns, reduced costs, and safer, more productive conditions for everyone involved.

What Exactly Does an Inspection Protocol Entail?

Fundamentally, it’s a useful document—well-structured, intuitive, and action-oriented.

An Industrial Facility Inspection Protocol separates your building’s key mechanisms into manageable classes: heating, ventilation, and air conditioning (HVAC), electrical, plumbing, safety systems, and more. Each inspection task is clearly assigned to an accountable individual, given a deadline, and connected to a checkbox that confirms completion. Notes or comments offer space for any necessary follow-ups or additional observations.

What may otherwise become a disorganized or overlooked set of duties becomes, through this form, a dependable, repeatable process.

Why Does It Prove So Beneficial?

Because in facility management, prevention always surpasses reaction—without exception.

🔧 Scheduled Maintenance

Regular reviews help uncover small issues before they multiply into expensive repairs. By maintaining a watchful eye on critical components, the protocol acts as an early-warning system that protects the building’s functionality.

🛑 Compliance with Regulations

Fire extinguishers, smoke detectors, and emergency exits must not only exist—they must function properly. Keeping inspection records ensures the facility remains in line with fire, health, and occupational safety regulations.

⚙️ Uninterrupted Operations

A single malfunction, such as an unexpected HVAC failure during a heat wave, can slow or entirely halt production lines. Implementing a rigorous preventative maintenance schedule helps keep all infrastructure running optimally.

💰 Cost Effectiveness

Proactive upkeep extends the useful lifespan of assets and machinery, decreasing unexpected expenditures and the total expense of possession over the long-term.

📁 Audit Preparedness

For regulated enterprises, maintaining thorough records of servicing is compulsory—not a choice. The checklist supplies traceability and reassurance during external and internal reviews.

What Should a Strategic Checklist Incorporate?

A skillfully constructed checklist does more than itemize jobs—it cultivates responsibility, ensures follow through, and establishes order.

🏗️ System Categories

Grouped into significant classifications like:

- General Facility

- Electrical

- HVAC

- Plumbing

- Safety

- Exterior Grounds

Each class centers on a different critical system, making sure no part of the building goes unevaluated.

✍️ Task Particulars

Every task features:

- The system inspected

- The person or team responsible

- Suggested frequency

- Upcoming due dates

- A status checkbox

Progress is simple to track, and notes permit staff to flag any issues requiring extra attention.

📜 Documentation

Every inspection entry incorporates:

- A date

- The responsible party

- Any observations or concerns

This long-term record aids teams reflect on tendencies and refine procedures over time.

Key Maintenance Areas to Monitor

A thorough checklist addresses all the essential elements of a structure, like:

- Building Framework: Inspect walls, floors, roofing, doors, and windows for signs of harm or wear.

- Electrical: Check control panels, lighting arrangements, backup generators, and emergency power setups.

- HVAC: Clean filters, inspect ducts, test thermostats, and confirm heating/cooling units are functioning efficiently.

- Plumbing: Look for leaks, test restrooms and kitchen fixtures, check drainage and water heaters.

- Safety Systems: Test smoke detectors, inspect fire extinguishers, confirm clear emergency exits and functioning signage.

- Exterior Grounds: Carefully survey outdoor spaces, walkways, fences, and signage for structural and safety problems.

Modernizing Routine Inspections

Today, digitization offers more than ease—it transforms processes.

Using electronic checklists or spreadsheet templates simplifies:

- Task scheduling

- Crew assignments

- Repair documentation

- Information sharing

Custom lists tailored exactly to your facility layout and machines ensure relevance and precision—no more generic, one-size-fits-all blueprints.

A Strategic Approach, Not Mere Paperwork

Checklists are more than just administrative tasks—they shape strategy by:

- Preventing lapses

- Enhancing workplace protection

- Lowering repair and replacement expenses

- Supporting smooth daily operations

Whether overseeing a lone building or many across regions, consistent checklists ensure nothing gets missed. It’s a simple habit with mighty results, establishing the foundation for a safe, efficient, and well-kept industrial operation.

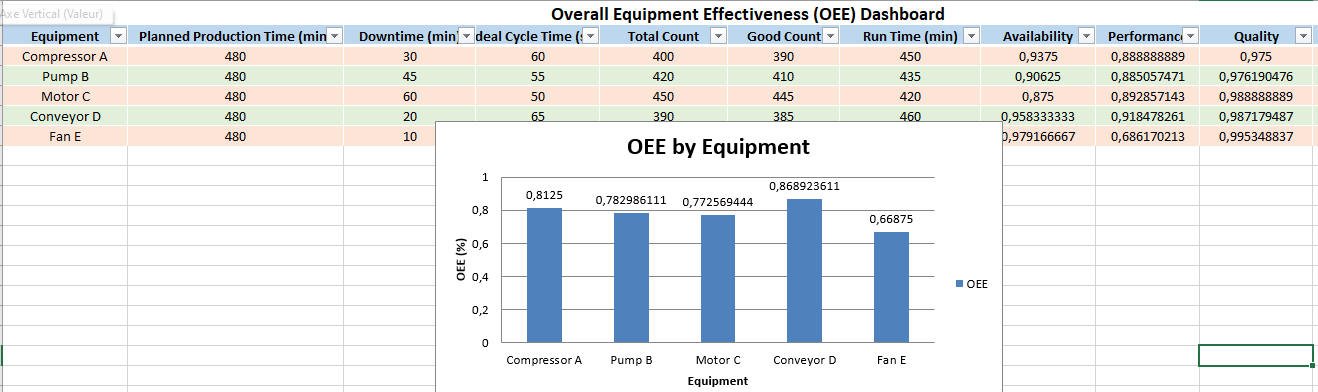

Key Performance Indicators (KPIs) for the Major Objectives of an Industrial Building Maintenance Checklist

Here are key performance indicators (KPIs) for the major objectives of an industrial building maintenance checklist, including Safety Compliance, Cost Control, Preventive Maintenance, and more:

✅ 1. Safety Compliance Indicators

These indicators help ensure the facility is operating within legal safety requirements:

| Indicator | Description | Target |

|---|---|---|

| Safety Inspection Completion Rate | % of scheduled safety inspections completed on time | 100% |

| Number of Safety Violations Found | Total violations identified during inspections or audits | As low as possible |

| Time to Resolve Safety Issues | Average time taken to fix identified hazards | ≤ 7 days |

| Employee Safety Training Compliance | % of staff who completed mandatory safety training | ≥ 95% |

| Accident Frequency Rate (AFR) | # of recorded incidents per 100,000 hours worked | Trending downward |

| Emergency Equipment Test Pass Rate | % of fire extinguishers, alarms, etc., that pass testing | ≥ 98% |

💰 2. Cost Control Indicators

These track how effectively maintenance costs are managed:

| Indicator | Description | Target |

|---|---|---|

| Maintenance Cost per Square Foot | Total maintenance spend divided by building size | Defined by budget |

| Reactive vs. Preventive Cost Ratio | Cost of unplanned vs. planned maintenance | ≤ 1:3 (more preventive) |

| Overtime Hours for Maintenance | Overtime hours worked due to emergency maintenance | ≤ 10% of total |

| Inventory Holding Costs for Spare Parts | Costs associated with storing unused spare parts | Within defined limits |

| Cost Avoidance Through Preventive Maintenance | Estimated savings from avoiding repairs | Year-on-year increase |

🔧 3. Preventive Maintenance Indicators

Track the reliability and scheduling of routine maintenance:

| Indicator | Description | Target |

|---|---|---|

| Planned Maintenance Completion Rate | % of planned tasks completed on time | ≥ 95% |

| Mean Time Between Failures (MTBF) | Average time between equipment breakdowns | Trending upward |

| Mean Time to Repair (MTTR) | Average time taken to fix equipment once broken | Trending downward |

| Equipment Availability | % of time equipment is available and functional | ≥ 98% |

| Number of Missed Maintenance Tasks | Scheduled tasks not completed | 0 |

🏭 4. Operational Efficiency Indicators

Ensure that maintenance contributes to optimal facility operation:

| Indicator | Description | Target |

|---|---|---|

| Downtime Due to Maintenance | Hours of lost production due to maintenance | Minimal |

| Work Order Backlog | Number of pending maintenance requests | < 10% of total capacity |

| Work Orders Completed on First Visit | % completed without follow-up visits | ≥ 90% |

| Technician Productivity | Tasks completed per technician per day | Defined by benchmark |

| Facility Condition Index (FCI) | Cost of deferred maintenance ÷ building replacement value | ≤ 0.05 |

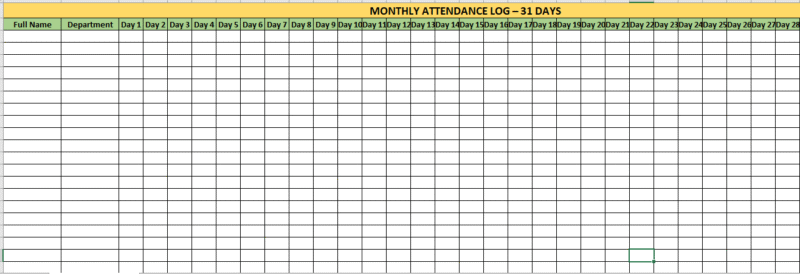

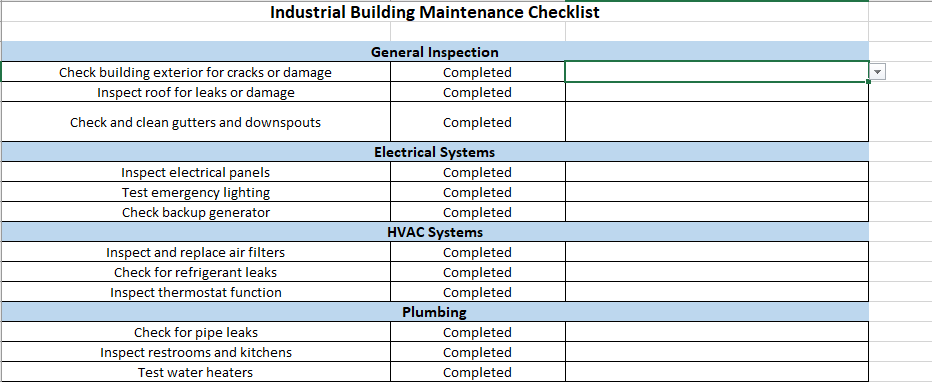

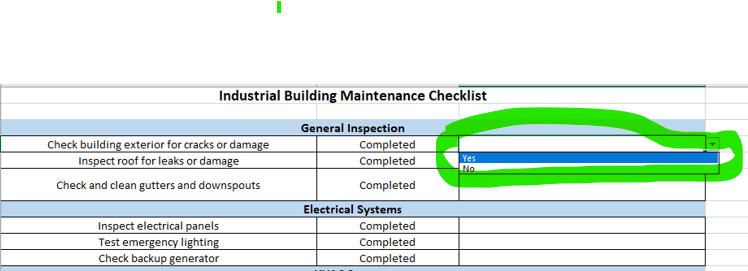

Industrial Building Maintenance Checklist

Purpose: A structured, single-sheet checklist for maintaining industrial buildings, divided by system.

Features:

- Title at the top: “Industrial Building Maintenance Checklist”

- Sections: General Inspection, Electrical Systems, HVAC, Plumbing, Safety Systems

- Columns:

- Maintenance Task

- Completed (Dropdown: Yes/No)

- Notes

- Styled with light blue headers and green task rows

- Central alignment, borders for readability

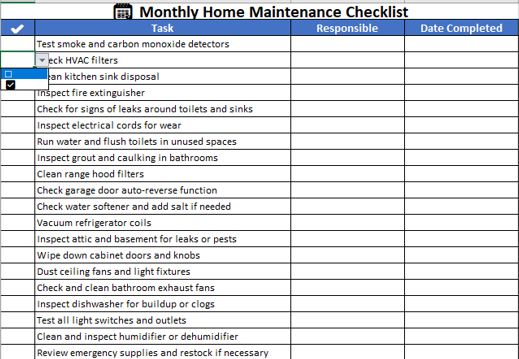

Bilingual Industrial Maintenance Checklist

Purpose: A bilingual (English/French) maintenance checklist for industrial buildings.

Features:

- Tailored for international or multilingual teams

- Bilingual Title

Sections: General Inspection, Electrical Systems, HVAC, Safety Systems

Columns:

- Task / Tâche

- Responsible / Responsable

- Due Date / Date d’échéance

- Done / Fait (Dropdown: Yes/Oui, No/Non)

- Colored headers and alternating row fills for clarity

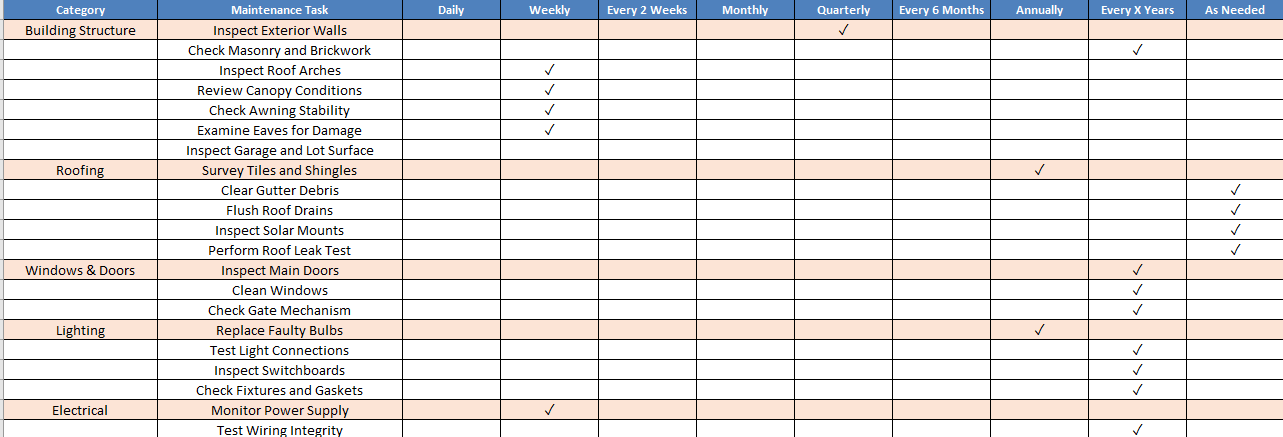

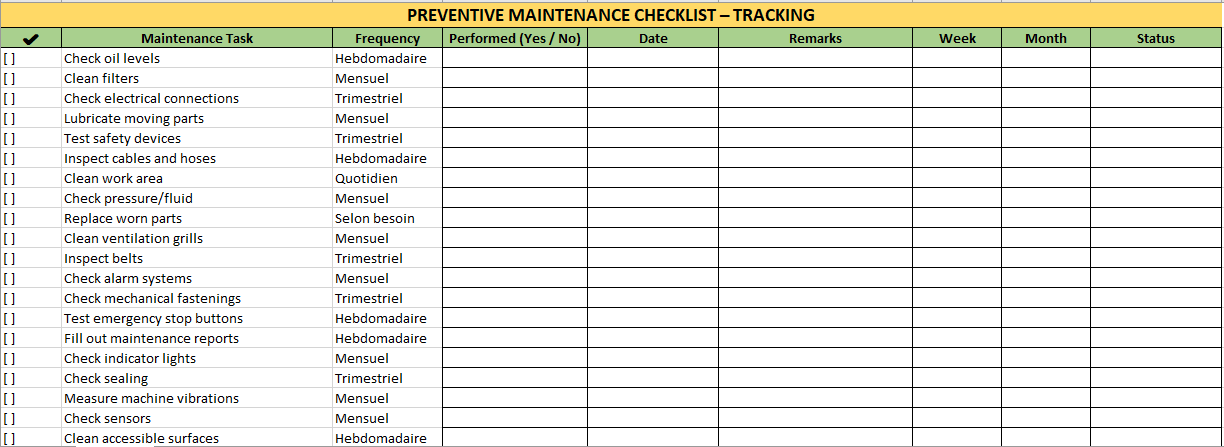

Preventive Maintenance Checklist

Purpose: Revised version of the huge checklist with improved content and color design.

Features:

- All cells bordered and centered for neat presentation

- Renamed sections (e.g., Building Structure instead of Structures)

- Modified tasks for clarity

- Modern color scheme:

- Blue header with white font

- Light orange-beige section headers

Same frequency columns (Daily to As Needed)