A Practical CMMS Maintenance with Excel: From Intake to KPIs

Recommandés

Maintenance teams don’t need yet another buzzword—they need a clear workflow that captures requests, plans work, controls cost, and proves results. This article walks you through a lean, Excel-based CMMS design that you can deploy today. It follows a simple but robust flow:

Requests → Approval → Work Orders → PM Plans → Parts/Inventory → KPI Dashboard

1) Why this CMMS design works

- Single source of truth: Assets, work orders, PMs, parts, vendors, technicians—each has a clean, validated table.

- Frontline first: A dedicated Requests page makes intake painless and traceable.

- Priority & SLA baked in: P1–P4 priorities and hour-based SLAs drive due dates and overdue flags.

- Measurable outcomes: A small set of KPIs (Open/Overdue WOs, PM compliance, MTTR, parts below ROP) gives leadership what they need without drowning the team in vanity metrics.

- Excel-native: No licenses, fast adoption, easy to customize, and works offline.

2) The data model—what to track and why

2.1 Assets (your registry)

Key fields: Asset ID, Class (e.g., Material Handling), Subclass (Conveyors, Pumps…), Location, Criticality, Warranty, PM next due.

Why it matters: A clean asset list unlocks targeted PMs, risk-based prioritization, and faster troubleshooting.

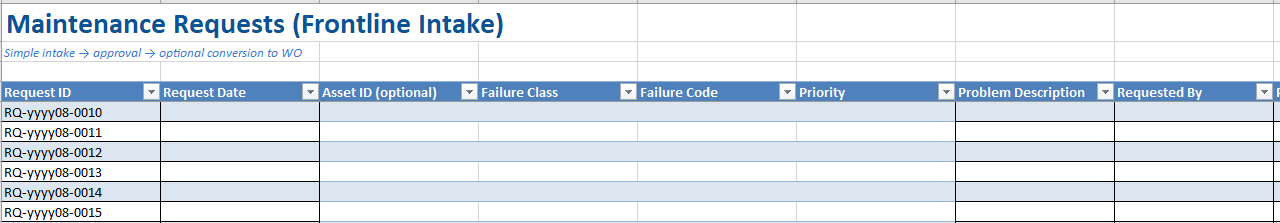

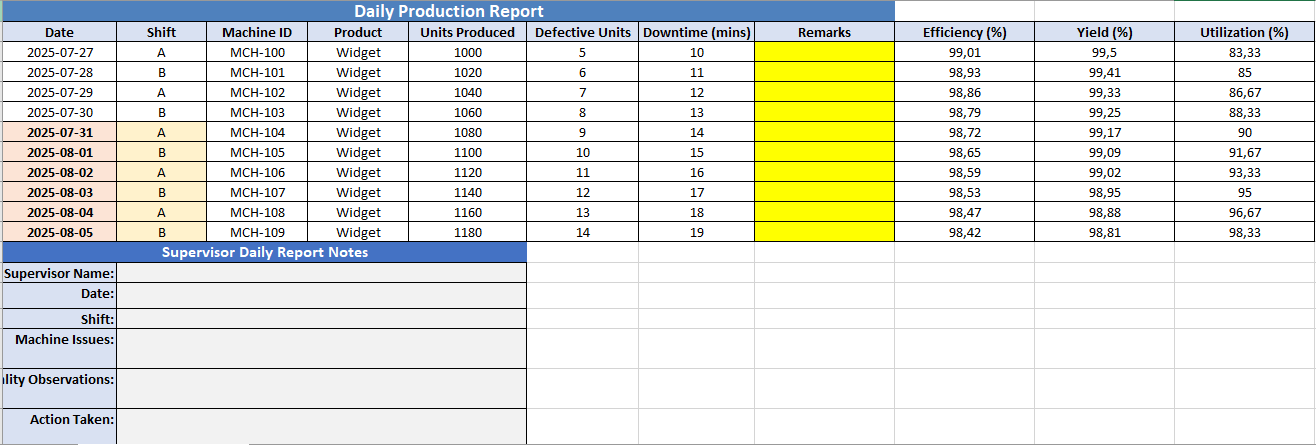

2.2 Requests (frontline intake)

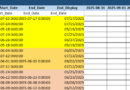

Key fields: Failure Class/Code, Priority (P1–P4), SLA hours, Approval Status (New/Approved/Rejected), Due By (auto), Overdue Days (auto).

Why it matters: Separating requests from WOs reduces noise and gives planners time to triage.

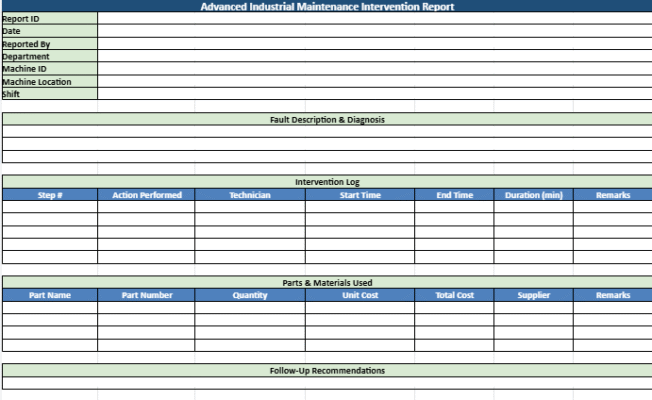

2.3 Work Orders (WO)

Key fields: Work Type (Breakdown/Preventive/Calibration/Improvement…), Status (New→Completed/Cancelled), Assigned tech, Downtime (h), Labor hours & rate, Parts cost, Total cost (auto), On-Time? (auto).

Why it matters: This is your execution backbone—link to a Request ID when a request becomes a WO.

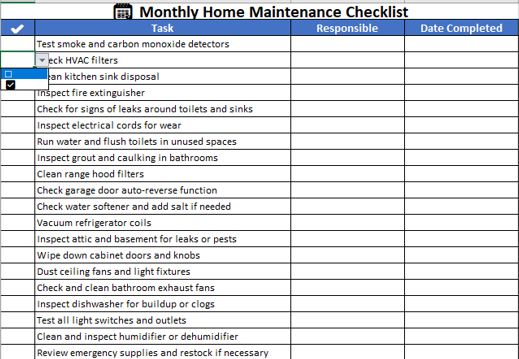

2.4 PM Plans

Key fields: Frequency Unit (Days/Weeks/Months/Years), Interval, Last Done, Next Due (auto), Days Remaining (auto).

Why it matters: PM compliance is your best lever to reduce breakdowns without increasing headcount.

2.5 Parts & Inventory

Key fields: On Hand, Reorder Point, Reorder Qty, Unit Cost, Stock Value (auto).

Why it matters: Low stock = longer downtime; excess stock = cash trapped on the shelf. ROP guards both.

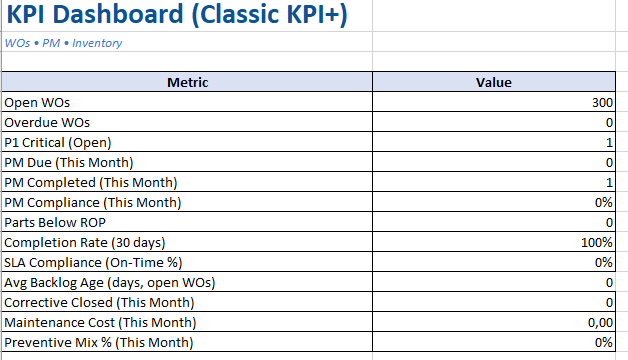

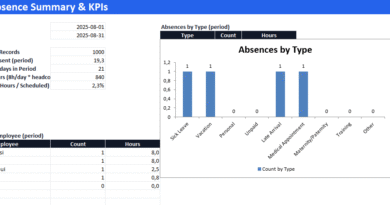

2.6 KPI Dashboard

Focus metrics:

- Open WOs and Overdue WOs (execution health)

- P1 Critical (Open) (risk exposure)

- PM Due vs. PM Completed → PM Compliance (preventive discipline)

- Parts Below ROP (supply risk)

- (Optional) MTTR (mean time to repair), MTBF (mean time between failures) if you log failure dates consistently

3) The operating rhythm (weekly cadence)

- Triage Requests

- Approve or reject. Set Priority and SLA.

- If work is needed, set To WO? = Yes, create a WO, and copy the Request ID into the WO.

- Plan Work Orders

- Assign technician(s), set Planned Start/End and Due Date (align to SLA if needed).

- Prepare parts and permits; add links in the WO “Description/Notes”.

- Execute & Close

- Record Downtime (h), Labor hours, Parts cost.

- Complete Root Cause / Corrective Action / Verification—don’t skip this.

- PM Discipline

- Review Next Due and Days Remaining.

- Hit the PM schedule before it turns overdue.

- KPI Stand-Up (15 minutes)

- Check Open/Overdue, P1 Critical, PM Compliance, Parts Below ROP.

- Agree one or two actions. Keep the loop tight.

4) Setting priorities, SLAs, and statuses that drive behavior

- Priority (P1–P4):

- P1—Critical: Safety risk, production stop, regulatory breach.

- P2—High: Major impact or high probability of escalation.

- P3—Medium: Routine but time-sensitive.

- P4—Low: Minor issues or opportunistic work.

- SLA (hours): Choose targets (e.g., 4/8/24/72/168). In the template, SLA drives Due By automatically on Requests—and Overdue Days once due.

- WO Status flow:

New → Approved → Scheduled → In Progress → Completed(orCancelled)

UseWaiting Partswhen supply blocks execution—this status surfaces in KPI as a constraint to remove.

5) Cost and reliability—what’s “good enough” to start

- Labor cost = Labor hours × Hourly rate (auto).

- Total cost = Labor cost + Parts cost (auto).

- Downtime (h): record only for breakdown WOs; don’t inflate numbers for PMs.

- PM compliance: start by measuring this month. Aim for ≥ 90% on critical assets.

Don’t chase perfect precision on day one. Consistent “good enough” data beats sporadic “perfect” data.

6) How to roll it out in 30–60–90 days

Days 1–30 (Stabilize intake & execution)

- Lock the Requests → WO pathway.

- Train technicians to close WOs with hours and simple root cause.

- Review Open, Overdue, P1 daily; clear the backlog.

Days 31–60 (Preventive & parts)

- Build PM Plans for your top 20% critical assets.

- Define ROP for fast-moving spares; add vendor info.

- Start the weekly KPI stand-up.

Days 61–90 (Improve & automate)

- Tighten SLA targets by priority.

- Add MTTR tracking for top failure modes.

- Consider a simple macro or Power Query to automate Request → WO conversion and monthly KPI exports.

7) Example applications

- Warehouse equipment (forklifts, dock levelers):

P1 for safety or blocked dock; PMs for 500-hour service; parts for tires, forks, seals; vendor response times as an additional KPI. - Process utilities (compressors, HVAC, pumps):

P1 for plant-wide outages; PMs on filters and lubrication; log overheating/vibration failures; track trend of downtime hours. - Packaging line (conveyors, palletizers, PLCs):

Use failure codes Misalignment/Clogging/Sensor Fault; tie PM compliance to startup scrap and rework.

8) Governance and roles

- Requesters (frontline): Submit clear problem statements; choose a reasonable priority.

- Planners/Supervisors: Approve, set SLA, convert to WO, schedule, stage parts.

- Technicians: Execute, log hours/parts/downtime; write short root cause + corrective action.

- Maintenance Manager: Owns KPIs, backlog health, and PM discipline; removes constraints (parts, access, permits).

9) Common pitfalls (and fixes)

- Everything becomes P1: Enforce definitions and require justification.

- WOs never close: Make closing with hours & parts part of the day’s work, not an afterthought.

- PMs always late: Shorten PM scope, increase frequency where appropriate, and schedule during predictable lulls.

- Data drift: Freeze column headers; use the built-in dropdowns and tables to avoid typos.

10) Extending the template

- Mobile intake: Add a simple Microsoft Forms/Google Forms that writes into the Requests sheet.

- Analytics: Use Power BI or Excel PivotCharts for trends (downtime by asset, cost by failure class, aging backlog).

- Compliance: Add calibration logs and certificate links for instruments; audit trails in a “Logs” sheet.

Lean CMMS in Excel: From Intake to Impact

A CMMS doesn’t have to be heavy to be effective. With a disciplined Requests → WO → PM cycle, clear priorities and SLAs, and a small set of meaningful KPIs, you’ll reduce downtime, control cost, and build trust with operations—using tools your team already knows

What it is

A lightweight, Excel-based Computerized Maintenance Management System that covers the full flow:

Requests → Approval → Work Orders → PM Plans → Parts/Inventory → KPI Dashboard.

It’s drop-down driven, works offline, and is easy to customize.

Who it’s for

Maintenance leads, planners, and technicians who need a practical CMMS without complex software—especially in warehouses, utilities, and production lines.

What’s inside (the sheets)

- Start: Home page with navigation links and live KPI tiles.

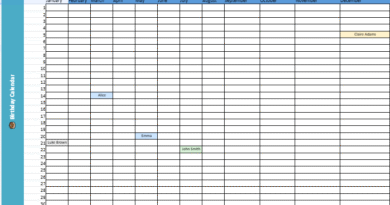

- Requests: Simple intake form (Priority P1–P4, SLA hours). Auto-calculates Due By and Overdue Days.

- Work Orders: Execution hub with Work Type (Breakdown/Preventive/…),

Status (New→Completed/Cancelled), assignee, Downtime (h), Labor/Parts cost, On-Time? flag. - Assets: Register with Class/Subclass, criticality, warranty, Next PM Due and Days to Due.

- PM Plans: Frequency-based (Days/Weeks/Months/Years) with auto Next Due + Days Remaining.

- Parts & Inventory: Min/Max/On-hand, Reorder Point, vendor, Stock Value (auto) + reorder alerts.

- Vendors & Technicians: Master data feeding dropdowns and cost rates.

- Parameters: All reference lists (priorities, statuses, work types, SLA targets, asset classes) in one place.

Built-in automation & logic

- Auto-IDs: RQ-/WO-/AS-/PM-/PT- prefixes with timestamps.

- SLA → Due date: Requests compute Due By from SLA hours; late items show Overdue Days.

- Costs: Labor Cost = Hours × Rate; Total Cost = Labor + Parts.

- PM math: Next Due from Last Done + Interval; Days Remaining counts down.

- Conditional formatting:

- Priority colors for P1–P4

- Overdue WOs highlighted

- Parts at/below ROP flagged

- KPIs (live): New/Approved requests, Open/Overdue WOs, P1 Open, PM Due vs Completed → Compliance, Parts Below ROP + small overview chart.

How to use (quick workflow)

- Log issues in Requests → set Priority & SLA, pick failure class/code.

- Approve & convert to Work Order (copy the Request ID into WO).

- Plan & execute in Work Orders → assign tech, dates, parts; capture hours, downtime, and root cause.

- Maintain PM Plans for critical assets and keep them compliant.

- Review Start/KPI weekly to chase Overdue/P1 and track PM Compliance.

Customize safely

- Edit drop-downs in Parameters (add your classes, failure codes, SLA targets).

- Add columns to the right of existing tables to avoid breaking formulas.

- Want one-click conversion from Request → WO or a French version? Easy to add.

What’s pre-filled

A few assets, technicians, requests, and WOs are seeded so dropdowns and KPIs work out of the box.

Limitations (by design)

- No macros (keeps it IT-friendly).

- Single-file approach—great for small/medium sites; large multi-site setups may prefer a database later.