Rethinking the 5S Checklist in Manufacturing: Excel Example

Recommandés

Download Excel 5S Checklist in Manufacturing ⬇️

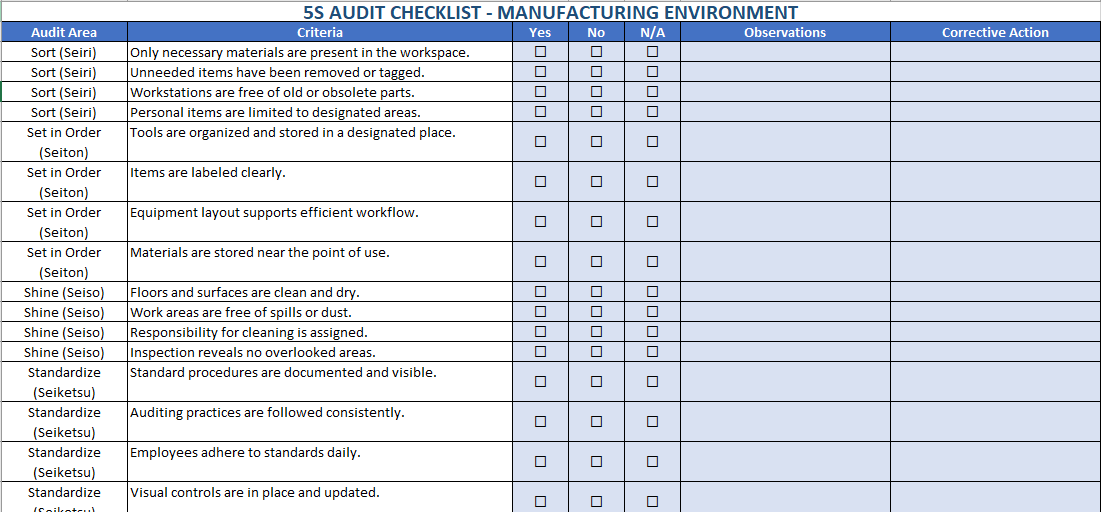

The 5S methodology has earned its place as a staple in lean manufacturing. But there’s a persistent issue: most content around the 5S checklist stops at the surface. It explains the five steps, lists a few generic criteria, and maybe adds a downloadable form. What it rarely does is address how to apply this tool in ways that adapt to real manufacturing environments — where teams are pressed for time, complexity varies by shift, and small inefficiencies compound into major problems

Instead of revisiting well-known definitions, let’s explore how the 5S checklist can evolve — from a static form into a dynamic driver of operational maturity. When tailored to site conditions, connected to performance metrics, and embedded in audit routines, the checklist becomes something more than a compliance exercise. It becomes a vehicle for continuous learning, daily improvement, and better outcomes.

First, Reframe the Role of the Checklist

It’s easy to treat the 5S checklist as a quality control form — another document for the binder or digital file system. But that’s too narrow a view.

A better approach is to see the checklist as a daily tool for decision-making. One that reinforces behaviors, flags potential risks, and captures early signs of operational drift.

This shift in mindset matters. When teams use the checklist not just to evaluate conditions, but to ask why those conditions exist, they uncover insights that don’t show up on dashboards or reports.

Build the Checklist Around Site Maturity

Not every manufacturing floor operates at the same level. Some are just starting to implement lean basics, while others are refining standard work at a granular level. Yet most 5S checklists are static — as if every environment faces the same challenges.

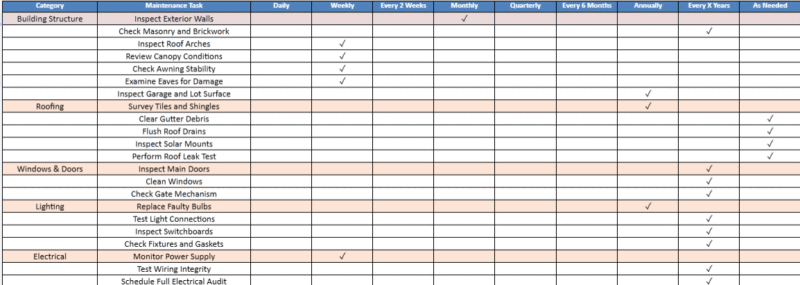

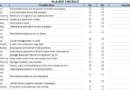

One of the most effective changes you can make is to design tiered checklists based on your team’s level of maturity:

- Basic Level: Focus on removing obvious waste, tagging excess materials, and marking zones.

- Intermediate Level: Include prompt questions to encourage root cause thinking. Add observations related to team behavior and consistency.

- Advanced Level: Link each audit category to specific standards, metrics, or documented procedures. Use scoring trends to support improvement cycles.

By scaling the checklist this way, you create a tool that not only tracks what’s happening — it develops people while doing so.

Make the Checklist Visual, Not Text-Heavy

On the floor, time and clarity matter more than documentation elegance. Many teams don’t have time to decipher dense checklists with long-form questions. That’s why your checklist should be visual.

Here’s how that looks in practice:

- Use icons for “yes,” “no,” or “needs attention” rather than open text boxes.

- Incorporate photos of good vs. poor conditions next to each criterion.

- Add color-coded sections to guide reviewers on what to focus on.

- Consider QR codes linked to training clips or standard work instructions.

This format cuts down ambiguity and allows team leads or line workers to engage quickly and accurately, without needing detailed instruction each time.

Downloadable: Visual 5S Checklist for Manufacturing Teams

Layer the Checklist into Routine Audits

Too often, the 5S checklist appears during annual reviews or sporadic cleanup days. But to be effective, it should become part of the daily rhythm — layered into how different levels of the organization interact with the floor.

A well-integrated audit structure might look like this:

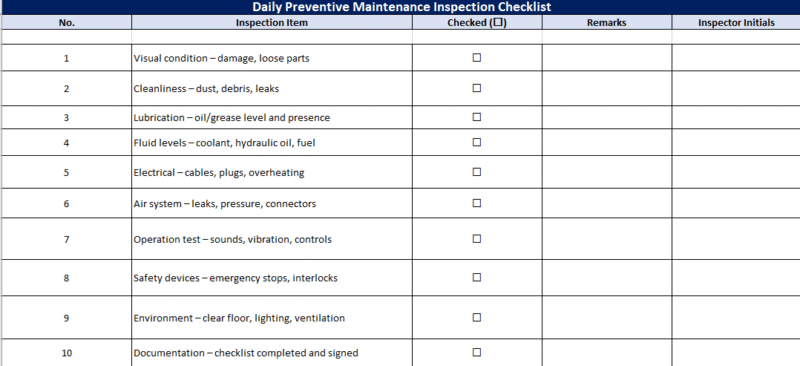

- Operators run a basic visual check at the start of each shift.

- Supervisors review once per week using a more detailed checklist.

- Managers audit monthly, looking at trends across multiple zones or teams.

- Executives or CI Leaders evaluate quarterly, focusing on systemic patterns or cultural gaps.

With this layered model, the checklist serves multiple purposes: immediate awareness, team accountability, leadership alignment, and long-term insight.

Read more: Developing a Layered Audit Model Using 5S

Link 5S Scores to Key Operational Metrics

This is where most organizations miss the mark.

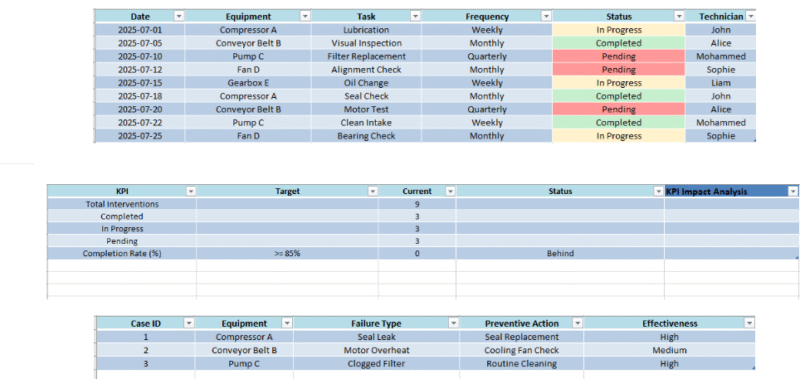

They perform audits. They log scores. But the data doesn’t go anywhere — and that’s a missed opportunity. If you want your 5S efforts to drive real outcomes, you need to connect checklist results to measurable performance.

Here are a few practical linkages:

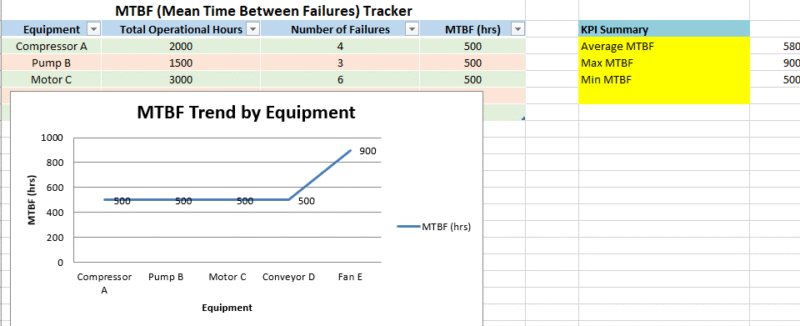

- Lower “Shine” scores may correlate with rising equipment failures due to dust or overlooked leaks.

- Weak “Set in Order” sections might predict longer changeovers or mislabeling errors.

- Consistent “Sustain” performance can indicate fewer line stoppages or improved right-first-time rates.

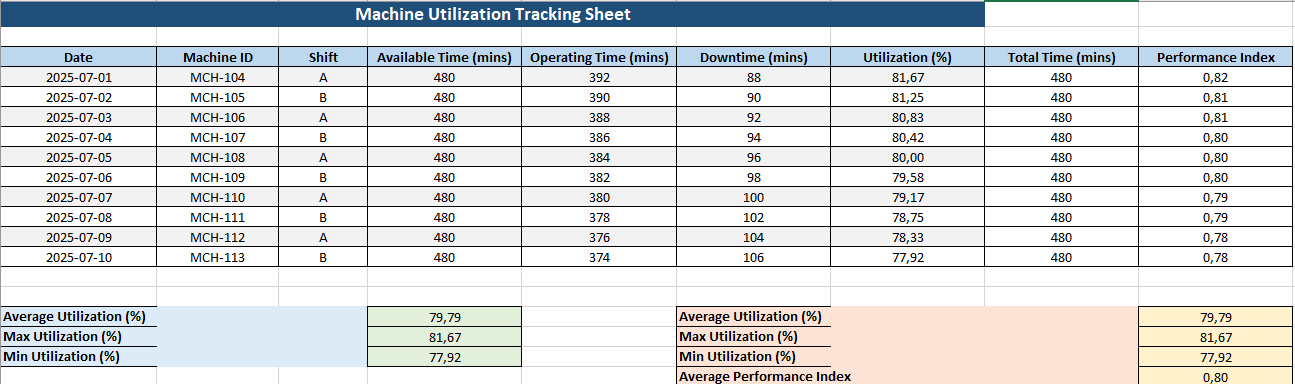

Start simple: overlay your 5S scores against metrics like downtime, waste, or safety incidents. Patterns will emerge — and you’ll have the data to support targeted changes.

Implementation guide: Using 5S Data to Improve Plant KPIs

Train Audit Leaders to See and Think

The checklist is only as effective as the person holding it. Many audits fall short because the focus stays on surface-level issues — clutter, labeling, cleanliness — without getting to the “why.”

That’s why audit training matters.

Build a short coaching module that helps supervisors or team leads go beyond evaluation. Teach them to ask open-ended questions, note behavior patterns, and spot signs of standards slipping.

For example:

- “Why do tools keep returning to the wrong bin?”

- “Is this area too crowded for the workflow?”

- “Was today’s deviation a one-off or part of a trend?”

These questions lead to meaningful improvement — and help everyone involved view the checklist as a guide, not just a form.

Internal tool: 5S Audit Coaching Kit for Floor Leaders

Close the Loop With a Response Process

What happens after the audit is just as important as the audit itself.

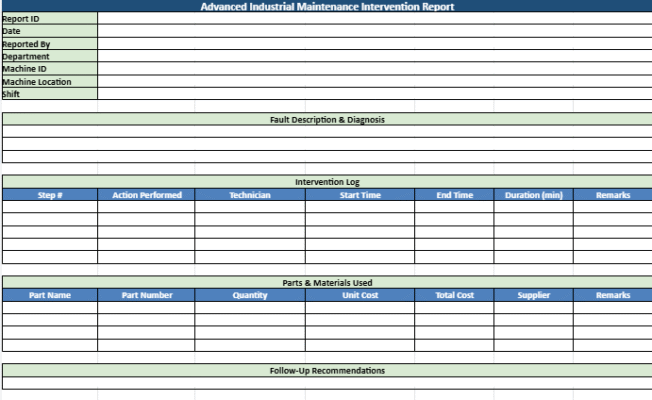

To avoid checklist fatigue, build a response process that assigns actions, tracks resolution, and reviews impact. This could be as simple as a three-step follow-up:

- Document the observation and its category.

- Assign a responsible person and a due date.

- Verify completion in the next audit cycle.

Over time, this process creates ownership, improves audit quality, and reinforces accountability. It also makes it easier to show progress during internal reviews or external audits.

Template: Simple Action Tracking Sheet for 5S Issues

From Form to Framework

If the 5S checklist is just another document your team completes out of obligation, it won’t move the needle.

But if it becomes a framework for coaching, continuous improvement, and standardization, it earns its place as one of your most useful tools. The difference lies not in the form itself, but in how it’s applied — with consistency, purpose, and a mindset that improvement is never finished.

⬇️

What Comes After the 5S Checklist? Turning Audit Insights Into Operational Change

Completing a 5S checklist is easy. Acting on it — consistently, intelligently, and sustainably — is where most organizations stall.

It’s a common cycle: teams run regular 5S audits, record findings, maybe even post scoreboards. But results rarely lead to meaningful change. Issues recur, root causes go unaddressed, and the checklist gradually becomes routine paperwork.

The problem isn’t the checklist. It’s the lack of a system for interpreting and acting on what the checklist reveals.

This article explores what comes next — how to build the infrastructure and culture that converts audit data into tangible improvements. If you’re serious about making 5S more than a visual tool, this is where your focus should shift.

Step One: Recognize the Patterns, Not Just the Problems

Many teams respond to audit failures individually: a missed cleaning task, a mislabeled bin, a cluttered area. These are corrected — but the larger trends go unnoticed.

The first step is learning to treat audits like a feedback system, not a to-do list.

Here’s how:

- Review not just scores, but the categories that fail most often.

- Track repeat issues by team, shift, or cell.

- Identify where non-compliance is highest — and why.

For example, if “Shine” consistently scores low in one area, is it a problem of time allocation? Ownership? Or perhaps equipment layout that encourages debris?

A pattern of failure points toward a process issue, not just a compliance lapse. That’s the insight that leads to sustainable improvement.

Related article: How to Build a 5S Trend Dashboard in Excel

Step Two: Build a Visual Escalation System

Not every 5S issue needs a formal project. But some do.

Without a way to escalate persistent issues, teams are left frustrated. Frontline operators fix what they can, but systemic problems — layout inefficiencies, inadequate storage, underdeveloped standards — linger.

To close this gap:

- Create a color-coded escalation chart for audit findings (e.g., green = local fix, yellow = team lead support, red = cross-functional improvement).

- Define which audit scores trigger reviews at different levels of leadership.

- Assign timeframes for response, and make resolution status visible on team boards.

This structure provides clarity and reinforces the idea that audit data is meant to drive decisions, not just compliance.

Template: Escalation Matrix for 5S and Layered Audits

Step Three: Connect 5S Gaps to Process Losses

5S is often siloed from broader improvement efforts. That’s a mistake.

A disorganized tooling cabinet doesn’t just fail an audit — it adds changeover time, increases motion waste, and may even contribute to quality issues.

The most effective sites translate 5S failures into their operational language:

- Audit gaps = process losses

- Low scores = hidden cost drivers

- Recurring issues = risks to delivery or safety

If your team already tracks metrics like OEE, downtime, scrap, or labor utilization, find ways to overlay 5S scores onto those metrics. You may find that poor 5S zones also show lagging KPIs.

Guide: Mapping 5S Failures to Value Stream Performance

Step Four: Make Ownership Local but Visible

Improvement only sticks when it’s owned by the people closest to the problem.

But ownership isn’t enough. What’s often missing is visibility of that ownership — who’s fixing what, by when, and with what result.

Here’s what that can look like:

- Assign 5S action items with names and due dates during each audit cycle.

- Post unresolved items with aging indicators (e.g., days since issue was logged).

- Celebrate not just successful audits, but successful resolutions — especially when team members propose their own solutions.

This builds a culture of closed-loop problem-solving without needing new software or process changes. It starts with accountability and trust.

Related post: Building a Visual Action Tracker from Audit Results

Step Five: Use Audit Trends to Shape Training

If your 5S scores have plateaued, chances are your training has too.

Audit data is a powerful signal for where and how to invest in skill building. When scores in “Standardize” drop, maybe teams aren’t confident in interpreting visual controls. If “Sustain” is lagging, the team may not understand the purpose behind daily checks.

Use this data to:

- Run quick refresher workshops on specific 5S steps

- Incorporate checklist items into onboarding or cross-training

- Create job aids tied to weak audit areas

When your people understand why each audit point matters — not just what it is — results improve. That’s how you turn routine checklists into learning systems.

Explore: Micro-Training Modules for 5S Maturity

What You’re Building: A Loop, Not a List

The real value of the 5S checklist isn’t the form itself. It’s the feedback loop it creates.

Here’s the loop in action:

- Observe → Audit reveals a deviation.

- Interpret → Team identifies the cause.

- Act → Responsible person implements a solution.

- Reflect → Audit confirms resolution or triggers escalation.

- Improve → Patterns shape training, layout, or process changes.

That loop repeats daily, weekly, and monthly. Over time, it builds discipline — not just order. And that’s what separates cosmetic 5S from operational excellence.

Don’t Let 5S Plateau

If you’ve already introduced 5S, that’s a start. But if audits don’t lead to meaningful changes, they’ll soon feel empty — for team members and leaders alike.

The next step is to treat 5S not as a visual program, but as a behavioral feedback system. When you use audit results to drive action, learning, and performance, 5S becomes more than a tool. It becomes part of how your organization improves, every day.

- Foundational Guide: 5S Checklist for Manufacturing Environment

- Advanced Guide: Turning 5S Audits into KPI Gains

- Training Framework: Building Audit Skills at All Levels

- Tools & Templates: Visual 5S Audit Boards + Action Trackers