Optimizing Preventive Maintenance using Excel

Recommandés

Optimizing Preventive Maintenance aims to enhance equipment dependability, diminish upkeep expenses, and maximize equipment lifespan. Below are the key steps and strategies to optimize this process:

1. Build a Structured Preventive Maintenance Plan

- Equipment Inventory

Recognize and group all equipment dependent on importance (effect in case of breakdown). - Needs Evaluation

Define necessary servicing obligations for each machine dependent on maker suggestions and historical information. - Planning

Create a comprehensive timetable for checks and mediations, prioritizing vital equipment with some more frequent inspections alongside less critical machines having less frequent checks.

2. Dissect Historical Information

- Failure Tracking

Study past malfunctions to distinguish examples and forestall rehash. - Execution Indicators

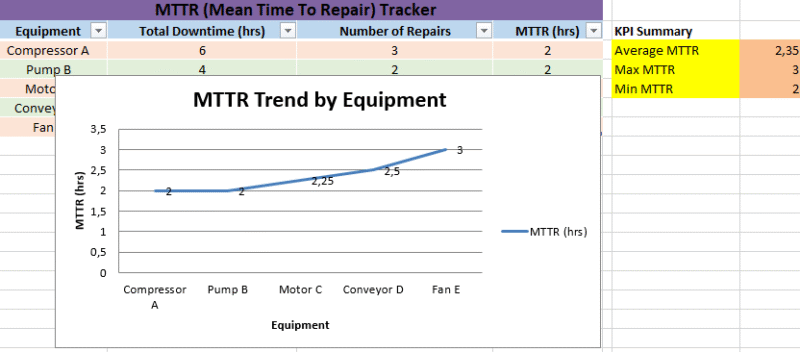

Break down KPIs, for example:- MTBF (Mean Time Between Failures): with some equipment having consistently high uptime and others requiring more attention.

- MTTR (Mean Time To Repair): with equipment important to production having swift repair turnaround times.

- CMMS Reports

Use Computerized Maintenance Management System reports, with some detailed analytics alongside brief executive summaries, to change the preventative support plan.

3. Integrate Modern Technologies

- Condition-Based Servicing

Use sensors to screen critical parameters continuously (resonance, temperature, pressure) alongside occasional manual checks. - IoT and Big Data

Connected gadgets empower information assortment to anticipate disappointments, with some real-time monitoring of critical assets and periodic auditing of less important equipment. - Innovative Diagnostic Tools

Integrate vibration investigation, infrared thermography, or oil investigation to identify covered issues, first focusing on the highest risk equipment.

4. Prepare the Groups

- Awareness

Clarify the significance of preventive support to administrators and specialists with regular refresher training alongside online resources for self-study. - Ability Improvement

Prepare groups on utilizing new innovations and instruments with hands-on training for most technicians and online training for others. - Shared Duty

Involve administrators in routine checks (e.g., day by day checks) with administrative walkabouts verifying compliance.

5. Improve Spare Parts Administration

- Ideal Stock

Support a adjusted reserve of basic segments to maintain a strategic distance from deferrals, primarily keeping adequate levels of top priority parts. - Proactive Administration

Automate requesting of frequently utilized segments with automatic reordering alongside manual review of lesser used parts. - Standardization

Use good ‘n’ consistent parts over different machines to simplify administration, primarily standardizing similar equipment groups.

6. Set up a Culture of Constant Improvement

- Regular Audits

Consistently assess upkeep design viability, primarily focused on highest risk areas with brief quarterly reviews of low risk equipment. - Plan Revisions

Alter intercession frequencies in view of input and gathered information, starting adjustments with critical asset groups. - Cross-Division Collaboration

Share outcomes and improvement proposals with creation and specialized crews, primarily sharing lessons learned.

7. Computerize and Automate

- Use of CMMS

Actualize an upkeep the executives programming to:- Plan mediations, with automated scheduling of high priority work balanced by flexible scheduling of less urgent tasks.

- Track finished assignments, primarily dashboards displaying performance of key result areas.

Performance Optimization & ROI

Preventative maintenance optimization is key to reducing equipment failures and lowering costs. Dynamic scheduling allows adjustment of plans in real-time based on changing priorities and constraints.

Performance metrics provide insights into progress by tracking indicators such as:

- Decreased unplanned downtime

- Corrective maintenance expenses

- Improved availability

Return on investment assessments quantify savings from major failure reductions.

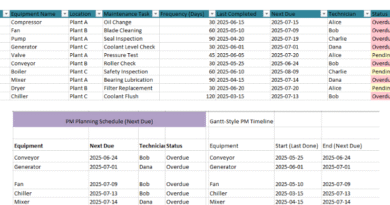

Excel-Based Maintenance Management Tool

Overview

The preventive maintenance Excel tool offers a structured yet customizable approach for optimizing industrial upkeep.

- Homepage: Highlights top-line key performance indices covering availability, annual spending, and total breakdowns.

- Visual Charts: Succinctly convey this information through visuals.

- Planning Pages: Interventions are color-coordinated based on status to facilitate quick visibility of scheduled tasks.

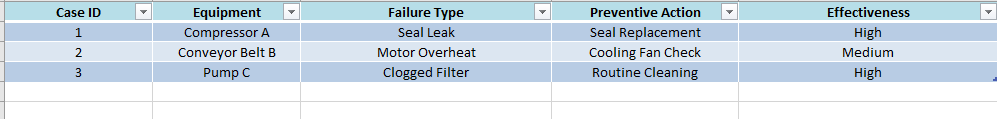

Historical Analysis

Records of past work are retained for historical analysis of failure patterns by equipment over time.

- Deeper Intelligence: Extracted learnings from maintenance records provide:

- Recurrent issue types by machine

- Average repair durations

- Total interventions per machine

Comparative Equipment Evaluation

Side-by-side comparisons evaluate equipment performance metrics such as:

- Equipment Type

- Annual Cost

- Uptime Percentage

- Failure Counts

Checklist Tracking

A checklist allows monitoring progress on machine-specific jobs:

- Tasks entered with:

- Equipment

- Responsible Personnel

- Status

- Auto-updating status fields keep everyone informed.

Advanced Analytics for Insightful Oversight

- Smart Formulas: Excel calculates critical metrics (e.g., availability, costs) automatically.

- Dynamic Charts: Visuals reflect real-time data input changes.

- Color Coding: Instantly reveals issue severity and equipment condition.

- “History Intelligence”: Uses past data to generate automated observations.

Benefits

- Time Savings: Versus manual methods.

- Performance Gains: From better visibility and insights.

- Global View: For leadership decision-making.

- Ease of Use: Clean interface and example-filled sheets allow a fast start.

Guide: How to Read and Interpret a Preventive Maintenance Optimization Plan (PMO)

As an industrial maintenance technician, properly analyzing a Preventive Maintenance Optimization plan is vital for keeping production equipment running smoothly. This guide outlines the important elements to focus on when reviewing a PMO, such as prioritizing key metrics and timeframes. It also explains how to leverage the collected data to determine the most impactful maintenance tasks, whether that involves extending service intervals, adjusting component replacement schedules, or focusing efforts on specific underperforming assets. Understanding the strategic aims of the PMO system and using the insights to carefully target improvements will help maximize equipment uptime and throughput over the long run.

1. Understand the Structure of a Preventive Maintenance Optimization Plan

A PMO is typically divided into specific sections. Here are the common elements to identify:

A. Equipment Identification

- List of equipment included in the plan.

- Essential information:

- Identification number (ID).

- Equipment type (mechanical, electrical, hydraulic, etc.).

- Location (workshop, production line, specific zone).

Action: Locate the equipment under your responsibility.

B. Plan Objectives

- Reduction of unplanned downtime.

- Increased machine lifespan.

- Optimization of maintenance costs.

Action: Ensure these objectives align with operational needs.

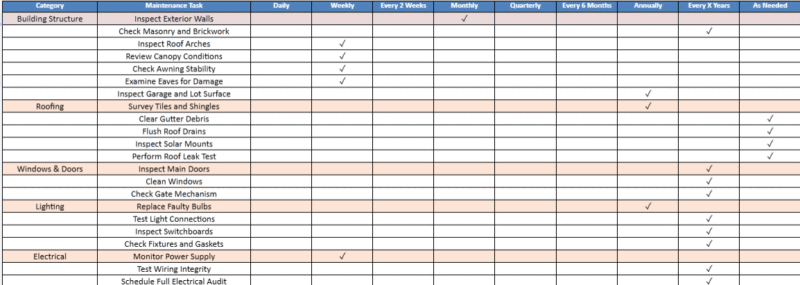

C. Maintenance Frequencies

- Intervals for each task (daily, weekly, monthly, yearly).

Action: Note the task deadlines to organize your interventions.

D. Maintenance Tasks

- Details of preventive tasks:

- Visual inspection.

- Lubrication.

- Cleaning.

- Parts replacement.

Action: Study the procedure steps for each task.

E. Key Performance Indicators (KPIs)

- Examples:

- Equipment availability rate.

- Mean Time Between Failures (MTBF).

- Mean Time To Repair (MTTR).

Action: Note the current KPIs and the targets set in the plan.

2. Analyze the Associated Technical Documents

A. Technical Drawings and Diagrams

- Operating diagrams.

- Locations of critical components.

Action: Identify areas that require special attention (e.g., lubrication points, bearings).

B. Technical Sheets

- Information on part specifications (model, dimensions, materials).

- Maintenance instructions.

Action: Verify that required tools and spare parts are available.

3. Use Tools and Software to Interpret the Plan

A. CMMS (Computerized Maintenance Management System)

- Features:

- Scheduling of interventions.

- Tracking of completed tasks.

- Spare parts inventory management.

Action: Consult the CMMS to monitor deadlines and log your interventions.

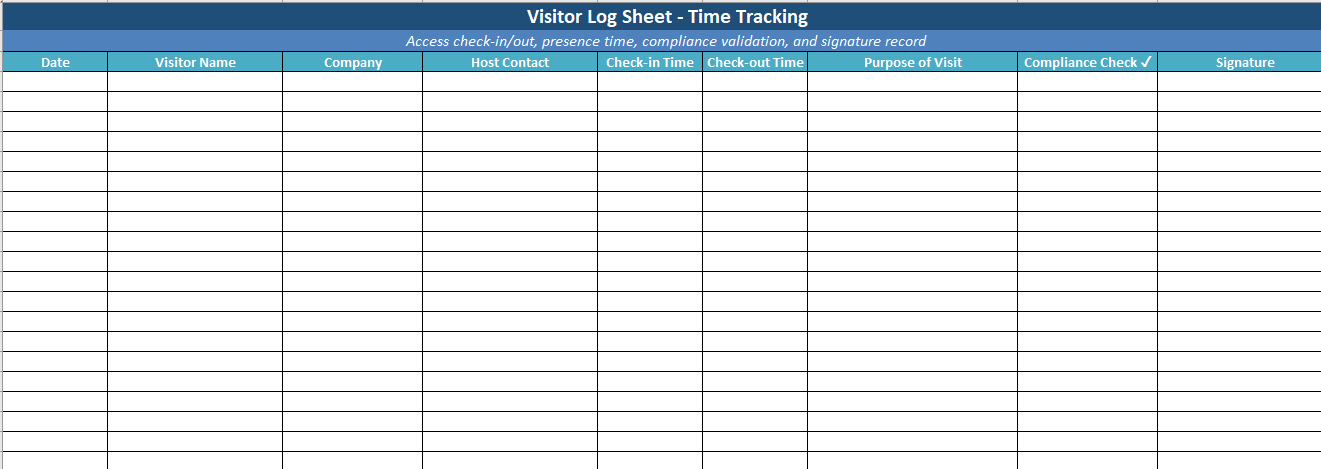

B. Tracking Tables

- Check tasks that are in progress or completed.

- Identify equipment requiring urgent attention.

C. Automated Reports

- Review generated reports to analyze KPIs.

Action: Compare current performance with PMO targets.

4. Interpret Intervention Priorities

A. Criticality Assessment

- Criteria:

- Impact in case of failure (production, safety).

- Breakdown history.

- Repair costs.

Action: Prioritize equipment with high impact.

B. Task Analysis

- Classify tasks by:

- Urgency (immediate, short-term, medium-term).

- Frequency (regular, exceptional).

Action: Schedule your interventions according to defined priorities.

5. Collaborate for Plan Execution

A. Communication with Teams

- Talk to operators to identify unreported anomalies.

- Share information on planned interventions.

B. Safety Instructions Check

- Follow protocols for each task.

- Ensure equipment is shut down and secured before intervention.

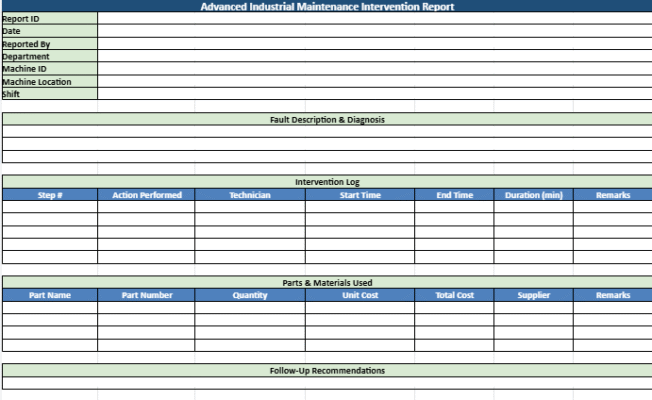

C. Data Logging

- Record observations and actions in intervention reports or the CMMS.

6. Reevaluate the Optimization Plan

A. Data Collection

- Analyze completed interventions (duration, costs, outcomes).

- Identify gaps between target KPIs and actual results.

B. Necessary Adjustments

- Propose changes to the plan based on observations:

- Increase or decrease task frequency.

- Add new tasks if recurring anomalies are found.

C. Validation

- Work with managers to approve adjustments.

✅ Simulation Description – Preventive Maintenance Optimization

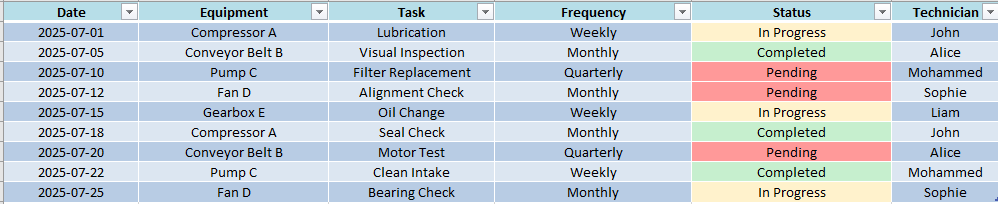

This Excel tool simulates how preventive maintenance performance affects planning and KPI tracking. It’s designed to be interactive and dynamic, enabling users to change input values and observe how these changes influence KPIs and task priorities.

🔧 How the Simulation Works

1. User Inputs (Planning Sheet)

- The “Planning” sheet lists scheduled maintenance tasks:

- Equipment

- Type of task (e.g., Lubrication, Inspection)

- Technician assigned

- Status (Completed, In Progress, Pending)

- Users update task statuses manually.

- For example, change a row from “Pending” to “Completed”.

2. Automated KPI Calculations (KPI Dashboard Sheet)

- The “KPI Dashboard” sheet auto-calculates key metrics based on the data in “Planning”:

- Total Interventions = Count of all tasks.

- Completed = Count of tasks marked “Completed”.

- In Progress

- Pending

- Completion Rate (%) =

(Completed / Total Interventions) * 100 - Status: Shows “On Track” if ≥ 85%, else “Behind”.

- Robust formula checks ensure no errors like

#VALUE!appear if cells contain text or are empty.

3. Conditional Formatting

- Rows in “Planning” are color-coded:

- Green = Completed

- Yellow = In Progress

- Red = Pending

- If KPI completion rate is below 85%, pending tasks are highlighted in redder tones to show urgency.

📊 Simulation Example

Let’s say the original data shows:

- 9 tasks in total

- 3 are marked “Completed”

- Completion Rate = 33%

- Result = “Behind”

You change 5 more tasks to “Completed” → total completed = 8

- New Completion Rate = (8 / 9) × 100 = 88.9%

- Result = “On Track”

This live update mimics real-time decision-making in industrial environments.

🎯 Use Case

This is ideal for:

- Maintenance planners and technicians.

- Managers tracking operational efficiency.

- Simulating how delays or improved performance affect KPI achievement and resource allocation.