📊 Maintenance KPIs: From Definition to Real Optimization

Recommandés

Modern industrial operations demand more than reactive maintenance; they rely on consistent performance and reduced downtime. Maintenance today is about ensuring smooth, uninterrupted operation over time. To know whether your strategy is actually delivering results, you need more than assumptions—you need measurable proof. That’s where Key Performance Indicators (KPIs) come in.

Although KPIs provide performance summaries, their true worth lies in driving choices, solving issues, and steady progress.

🔍 What Are Maintenance KPIs?

Maintenance KPIs provide quantifiable data on efficiency, quality, and impact. They serve as a report card showing advancement, stagnation, or decline.

Good KPIs don’t just tally tasks—they gauge consequences. They highlight strengths and weaknesses signaling needs for adjustment.

🧩 Core Maintenance KPIs and What They Mean

Let’s examine the most impactful measures, what each communicates, and how to calculate them:

1) MTTR (Mean Time To Repair)

Measures repair duration following failure.

Formula:

MTTR = Total Fix Time ÷ Number of Repairs

A lower score signals swift, skilled responses under pressure.

2) MTBF (Mean Time Between Failures)

Tracks uptime before breakdowns.

Formula:

MTBF = Total Operating Time ÷ Number of Failures

Lengthening MTBF demonstrates improving reliability.

3) Planned Maintenance Percentage (PMP)

Reveals planned-to-reactive work hours.

Formula:

PMP = (Planned Hours ÷ Total Hours) × 100

Higher PMP proves proactivity over reactionary firefighting.

4) Maintenance Cost per Unit of Output

Relates expense to production.

Formula:

Total Maintenance Cost ÷ Total Units Produced

Why it matters:

This KPI directly correlates maintenance efforts with production outcomes, making it exceptionally well-suited for return on investment discussions.

5) Equipment Availability

Fluctuates depending on scheduled operational periods versus downtime durations.

Formula:

Availability = Uptime ÷ (Uptime + Downtime)

Why it matters:

Directly impacts downtime issues and how prepared operations are.

6) Backlog of Work Orders

Unfinished maintenance tasks expand and contract over time.

Why it matters:

A prolonged growth could signify personnel shortfalls, scheduling problems, or inefficient processes requiring attention.

🧠 From Tracking to Optimization: Converting Observations to Actions

KPIs don’t automatically fix problems—they highlight areas demanding review. Here are wise ways to leverage them:

✅ 1. Establish Baselines and Compare

Initially, define current standards.

What’s the typical MTTR this month?

Which equipment has the worst MTBF?

Use these as “before” benchmarks. Then examine trends over time or across departments.

🔄 2. Seek Patterns, Not Isolated Data Points

A single dip may mean little—but consistently rising MTTR month-to-month or quarterly declining PMP flag deeper issues.

Focus on enduring tendencies, not standalone numbers.

🔧 3. Employ KPIs to Prioritize Concerns

Say an asset’s MTBF suddenly drops—thoroughly analyze its root causes before broader impacts.

Metrics aid choosing where limited periods and budgets create biggest value.

🔍 4. Investigate and Collaborate

Low availability? Could it stem from operator errors, poor maintenance planning, or design flaws?

Use KPIs to encourage chats between maintenance, production, and engineering teams.

5. Establish Realistic Objectives and Track Continuously

Overnight transformation from 60% to 95% availability is unrealistic—but steady 2–3% quarterly improvements are achievable.

Set incremental goals, and employ CMMS or spreadsheet dashboards to mechanically track and visually portray execution over time.

📈 Combining Metrics for Complete Visibility

A solitary indicator does not illustrate the full story. However, incorporate a few together, and you’ve obtained a lucid picture of what’s working and what’s not.

For example:

- High MTBF + Low MTTR = Very healthy machines

- Low PMP + Expanding backlog = Reactive upkeep taking over

- Increasing cost per unit + Flat production = Declining productivity

📘 Next Steps: Turning Maintenance KPIs Into a Continuous Improvement Engine

Now that you’re tracking maintenance KPIs, the real question becomes: What do you do with them? Numbers are only useful when they guide actions, shape decisions, and foster accountability. The next step in your journey isn’t just about having metrics — it’s about turning them into a system for smarter maintenance.

Here’s how to evolve from raw data to lasting operational gains:

🔧 1. Align KPIs With Your Business Goals

Your maintenance metrics should serve more than the maintenance department. They should link directly to what your company actually values:

- Is uptime your top priority? Focus on availability and MTBF.

- Trying to control maintenance costs? Track cost per unit of output or unplanned work ratios.

- Want better customer satisfaction? Ensure equipment reliability and product quality indicators are tight.

Tip: Make sure your KPIs speak the same language as plant leadership. That’s how you get buy-in and budget.

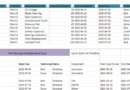

🧰 2. Build a Visual Dashboard (Not Just a Spreadsheet)

Your data needs to be visible and understood, not buried in tab 12 of an Excel workbook. A great maintenance dashboard:

- Highlights top-level KPIs (MTTR, MTBF, PMP, availability)

- Uses color coding (green/yellow/red) to signal status

- Includes trend lines to show progress or decline

- Offers slicers/filters to analyze by asset, technician, or timeframe

You want your team to glance and understand, not dig and guess.

3. Turn KPI Reviews Into Monthly Routines

You wouldn’t run a machine without checking it regularly. Your KPIs deserve the same.

- Set up a monthly maintenance KPI review — even 30 minutes.

- Discuss trends, not just numbers.

- Ask: “Why is this down?” or “What did we do right here?”

- Let techs and planners weigh in — insights often come from the floor, not just the screen.

Consistent reflection creates cultural ownership of the numbers.

4. Set Micro-Targets, Not Monster Goals

If your current Planned Maintenance Percentage is 30%, don’t aim for 90% by next month. You’ll burn out or fudge the data.

Instead, set realistic steps:

- “Let’s hit 45% PMP within the next 6 weeks.”

- “Let’s reduce MTTR by 10% for our top 3 bottleneck machines.”

Progress over perfection keeps the team motivated — and delivers sustainable improvements.

5. Root Cause, Not Just Reaction

When a KPI dips — say MTBF suddenly drops — dig deeper.

- Was the failure caused by wear? Improper use? Skipped maintenance?

- Are we missing a spare part we should stock?

- Should this asset be considered for redesign or replacement?

KPIs should never be static checkboxes. They’re starting points for action.

🔍 6. Share Wins Across Teams

If a department boosted availability by 15%, celebrate it — and more importantly, document how.

- What changes made the difference?

- Can other lines or sites replicate those practices?

- Who led the improvement?

KPI stories make metrics matter to everyone — not just analysts.

📈 Final Tip: Automate What You Can, Focus on What You Should

- Use Excel dashboards, CMMS tools, or Power BI to automate data capture and visualization.

- Free up your time to analyze trends, plan better, and prevent breakdowns.

- Don’t drown in data. Instead, let the data light the path forward.

KPIs Are Just the Beginning

Think of KPIs as your compass — they help you see where you are and where you’re drifting. But the journey is made through the adjustments you choose to make.

When used correctly, maintenance KPIs help you:

- Cut costs without cutting corners

- Build equipment reliability that production can trust

- Reduce stress and fire drills from reactive chaos

- Make smarter, faster, and more confident decisions

And most importantly — they move you from reactive to resilient.