Free Maintenance Intervention Report in Industrial Settings

Recommandés

In large factories where machinery seldom stops and the environment is unforgiving, basic checklists alone cannot ensure equipment reliability over the long run. What is required is a Advanced Maintenance Intervention Report, a nuanced tool enabling comprehensive documentation, insightful evaluation, and careful optimization of all maintenance activities. It grants organizations foresight into procedural strengths and weaknesses, empowering well-calibrated continuous improvement.

What Is a Maintenance Intervention Report?

A Maintenance Intervention Report is a structured document that records the details of any maintenance activity performed on equipment or infrastructure within a facility. Unlike basic logs or checklists, an advanced version of this report offers deeper insights by capturing multiple layers of information—from root cause diagnosis to technician actions, parts used, and future recommendations.

These reports serve not only as a historical record but also as a tool for continuous improvement, risk mitigation, and compliance documentation.

Why Is It Essential in an Industrial Environment?

✅ 1. Traceability and Accountability

The report clearly identifies:

- Who performed the intervention

- When and where it took place

- What actions were taken and why

This enhances operational accountability and ensures a clear chain of responsibility for each maintenance activity.

⚙️ 2. Root Cause Understanding

By capturing detailed fault descriptions and diagnostic notes, the report helps organizations move from reactive to proactive maintenance. Understanding the root cause enables teams to prevent recurrence rather than repeatedly fixing symptoms.

🔧 3. Step-by-Step Action Logging

A comprehensive intervention log records each step taken during the repair or servicing process, including:

- Action performed

- Start and end time

- Duration

- Remarks or observations

This timeline is invaluable for performance analysis and for training new personnel.

🧾 4. Parts and Cost Management

An advanced report includes a section for documenting parts and materials used, including:

- Part name and number

- Quantity used

- Cost per unit and total cost

- Supplier information

Tracking this data supports inventory control, budgeting, and supplier evaluation.

🔄 5. Follow-Up and Recommendations

Every intervention should end with insights. A follow-up section allows technicians or supervisors to note:

- Recommendations for future inspections

- Additional repairs needed

- Adjustments to maintenance schedules

This keeps the facility’s maintenance program dynamic and continuously improving.

How It Supports Broader Objectives

- Regulatory Compliance: Maintenance records are often mandatory for audits, certifications, or safety inspections.

- Downtime Reduction: Structured interventions help shorten repair times and improve first-time fix rates.

- Cost Control: Recording labor time and part usage allows for better financial oversight of maintenance operations.

- Knowledge Retention: Institutional memory is preserved when maintenance actions are well-documented, reducing dependency on individual expertise.

Key Components of an Advanced Report Template

A well-designed Maintenance Intervention Report typically includes:

| Section | Purpose |

|---|---|

| Report ID, Date, Technician | Identification and traceability |

| Equipment & Location Details | Context for the intervention |

| Fault Description & Diagnosis | Understanding the problem |

| Action Log | Documenting steps taken, with timing |

| Parts & Materials Used | Cost and resource tracking |

| Follow-Up Recommendations | Ensuring long-term system health |

From Paper to Digital: Optimizing the Workflow

While paper forms are still common, digitizing the maintenance intervention process can deliver even greater value:

- Auto-fill fields for technicians

- Drop-down menus for parts

- Instant cost calculations

- Searchable databases for audits and trend analysis

This not only saves time but also reduces the risk of errors and improves accessibility across departments.

An Advanced Maintenance Intervention Report is more than a form—it’s a decision-making tool, a communication bridge, and a compliance asset all rolled into one. For industrial facilities that prioritize performance, safety, and efficiency, investing in a well-structured, editable, and printable intervention report is not just beneficial—it’s essential.

What’s Next? Turning Reports into Results

Having a well-structured maintenance intervention report is a huge step—but the real value comes from what you do with the information.

1. Build a Maintenance History Library

Each report is a snapshot in time. But together, they create a powerful timeline—a maintenance history that reveals patterns. For example:

- Are the same issues recurring on certain machines?

- Are specific parts failing faster than expected?

- Is downtime happening more during one shift or season?

With this historical view, you’re no longer reacting. You’re planning, forecasting, and improving.

2. Use Data to Drive Preventive Maintenance

When reports show that a certain component typically fails after 1,000 operating hours, that’s not just trivia—it’s actionable insight.

You can start replacing that part at 900 hours, avoiding breakdowns altogether. Over time, these proactive changes:

- Increase machine lifespan

- Lower emergency repair costs

- Boost reliability and performance

3. Train Your Team With Real Examples

Training doesn’t always come from manuals. Sometimes, the best lessons are real-world fixes documented in your own factory.

Use past intervention reports in team meetings:

- Show what worked well—and what didn’t

- Reinforce safety steps and troubleshooting logic

- Share practical knowledge between shifts or locations

It builds confidence, consistency, and a culture of learning.

4. Set Benchmarks and Track KPIs

Once your reports are rolling in consistently, they become the foundation for maintenance KPIs (Key Performance Indicators):

- Average response time to breakdowns

- Time taken to complete each intervention

- Parts usage frequency

- Total cost per repair category

These benchmarks help you track efficiency, spot bottlenecks, and celebrate improvements.

5. Integrate With Digital Systems

If you’re using Excel today, that’s a great start. But eventually, you may want to integrate your reports into a Computerized Maintenance Management System (CMMS) or other digital platforms.

The benefits?

- Automatic reminders for upcoming service

- Easy part reordering

- Dashboards for real-time monitoring

- Centralized records across all departments

Best of all, it keeps your maintenance operation future-ready.

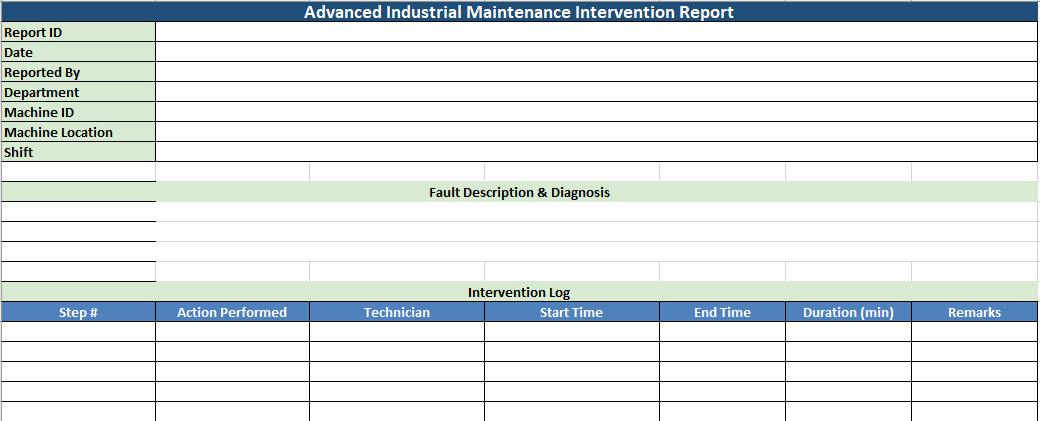

Advanced Industrial Maintenance Intervention Report Template

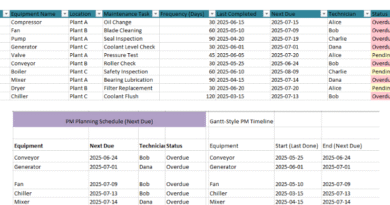

Here’s a detailed description of the last Excel file created:

Purpose:

This advanced template is intended for documenting repair jobs in industrial settings. It offers a thorough yet malleable, printable format for capturing: equipment malfunctions, technician steps taken, components utilized, labor logging, cost specifics, and post-work propositions. Such thorough documentation is highly suitable for factories, manufacturing centers, and establishments with intricate servicing duties. Meanwhile, at a small manufacturing plant nearby, the lead technician was faced with various issues across multiple systems throughout the day, requiring her to switch tasks between machines frequently to address problems as they arose, from a jammed conveyor belt to a broken compressor. After a long day of troubleshooting and repairs, she sat down to complete the comprehensive maintenance template, ensuring all relevant details of her work were logged for future reference and cost analysis.

- Equipment issues

- Technician actions

- Parts used

- Time tracking

- Cost details

- Follow-up recommendations

It’s ideal for use in factories, manufacturing plants, and facilities with complex maintenance operations.

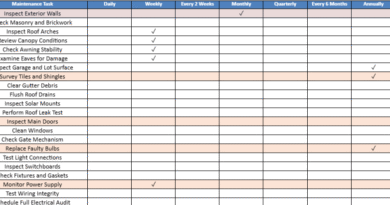

🧱 Structure & Sections:

1. Title Row

- Merged across columns A to G

- Title: “Advanced Industrial Maintenance Intervention Report”

- Bold white text on a deep blue background

- Easily printable as a formal report header

2. General Information (Rows 2–8)

Each row includes a label (left) and a merged editable field (right) for the following:

- Report ID

- Date

- Reported By

- Department

- Machine ID

- Machine Location

- Shift

Purpose: Helps identify the event and involved personnel.

3. Fault Description & Diagnosis (Rows 10–13)

- Titled section with merged cells

- Three rows of space to document:

- What failed

- Observations

- Root cause (if known)

Purpose: Helps analyze and understand the problem for future prevention.

4. Intervention Log Table (Rows 15–21)

Columns include:

- Step #

- Action Performed

- Technician

- Start Time

- End Time

- Duration (min)

- Remarks

Features:

- Pre-filled header row in white text with a blue background

- Five blank rows for multi-step repair actions

- Bordering and alignment for clean readability

Purpose: Provides a chronological and detailed view of the repair process.

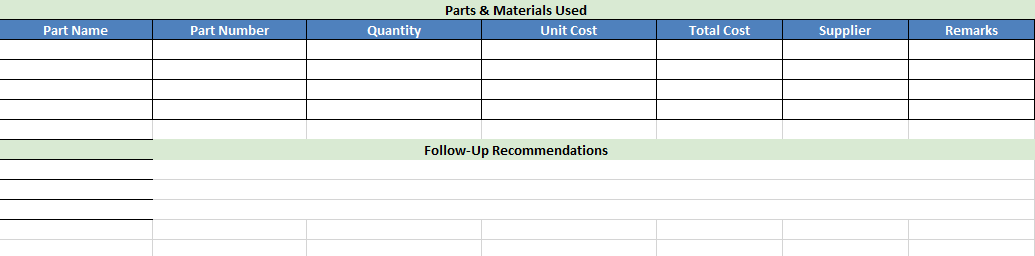

5. Parts & Materials Used (Rows 23–28)

Columns include:

- Part Name

- Part Number

- Quantity

- Unit Cost

- Total Cost

- Supplier

- Remarks

Use Case:

Tracks component usage and cost for traceability and budgeting.

6. Follow-Up Recommendations (Rows 30–33)

- Titled block with three editable lines

- Can include monitoring instructions, additional servicing needs, or scheduling reminders

Purpose: Ensures no loose ends remain and that next steps are planned.

🎨 Styling & Printability

- Professional color scheme (dark blue title, soft green headers, blue table headers)

- All cells are bordered and aligned

- Ready to be printed as a formal report or used digitally for editable entry